CLESCRANE suspension cranes leave your entire workshop area available for production. The cranes are simply attached to the existing roof structure – columns to support the crane runway are not needed. This design saves time and costs. Alternatively, the installation of stand-alone steel superstructures also enables the solution to be adapted to changed production requirements.

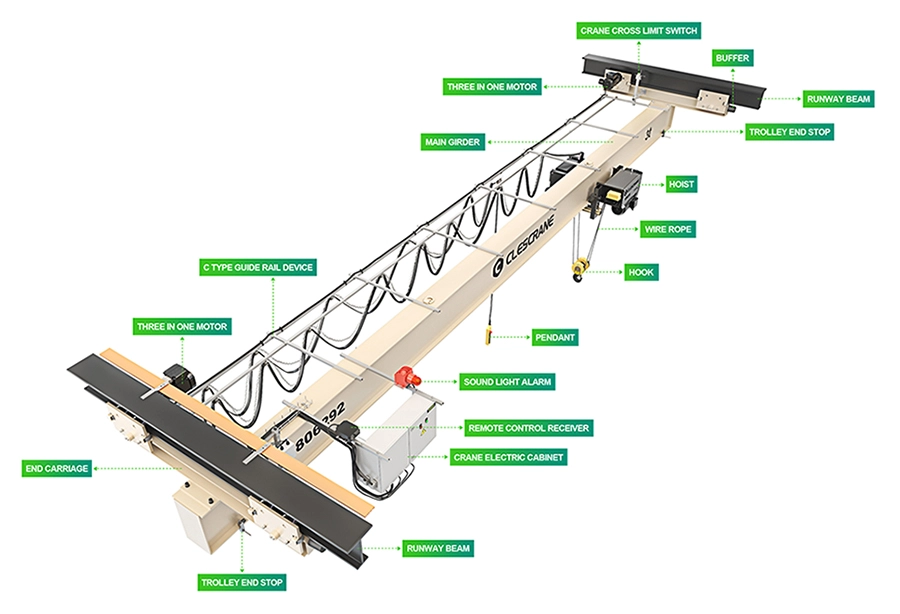

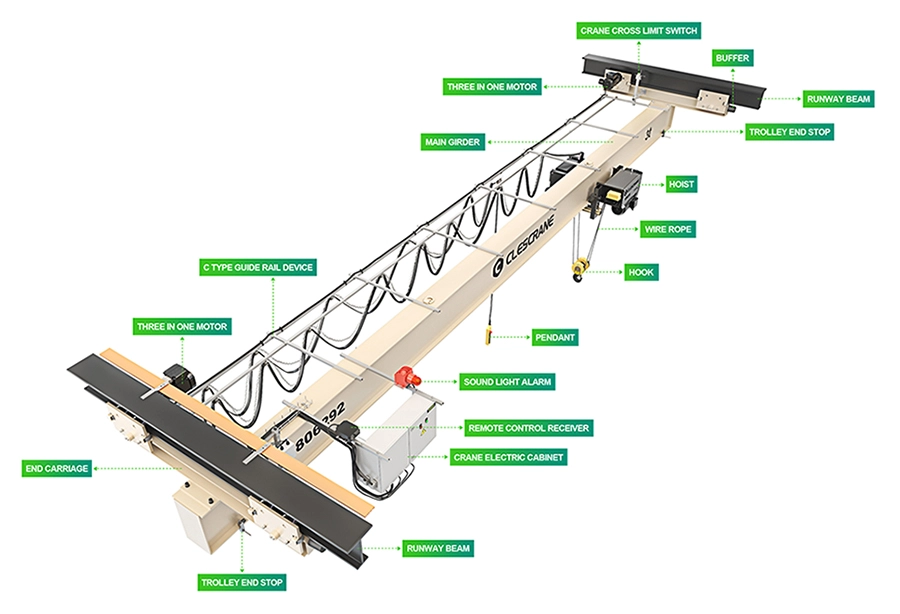

CHU series single girder suspension crane can be directly mounted under the existing roof structure.The rail adopts I beam and support rail beam no need to be installed. It helps you to make reasonable use of the existing plant.

Class A – This denotes standby or infrequent usage, such as cranes found in power utilities or motor rooms, where precise handling of equipment at slow speeds with long idle periods between lifts occurs.

Class B – This denotes light service, such as cranes used in repair shops or light warehousing, at slow speeds, with up to five lifts per hour up to maximum rated capacity.

Class C – This is for moderate service, such as those cranes installed in machine shops, including handling an average of 50% of the rated capacity up to 10 times per hour.

Class D – This is for denoting heavy service, such as cranes deployed in heavy machine shops, foundries, container yards, and more, where loads of 50% of the rated capacity are handled constantly.

Class E – This is for severe service, such as cranes found in scrap yards, cement mills, lumber mills, and more, where the crane makes 20 or more lifts per hour at or near its rated capacity.

Class F – This denotes continuous severe service, including custom-designed specialty cranes, that handle loads approaching the maximum rated capacity non-stop under extreme conditions.