1. Design is based on FEM and CMAA70 standards.

2. With optimizing design and low headroom, the crane height is greatly reduced, to achieve higher lifting height under the same plant height.

3. With optimizing design and low wheel pressure, the crane height is greatly reduced, to achieve greater lifting capacity weight under the same strength of the workshop.

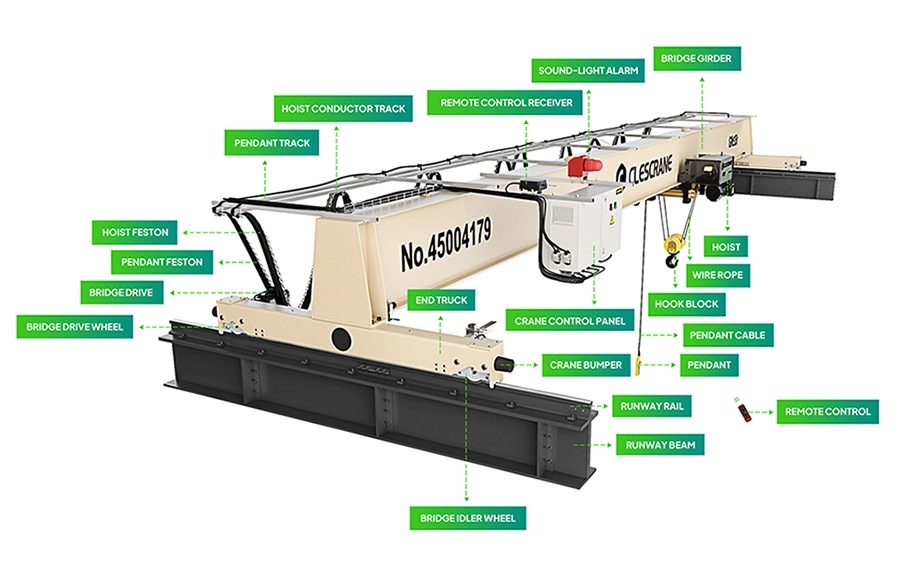

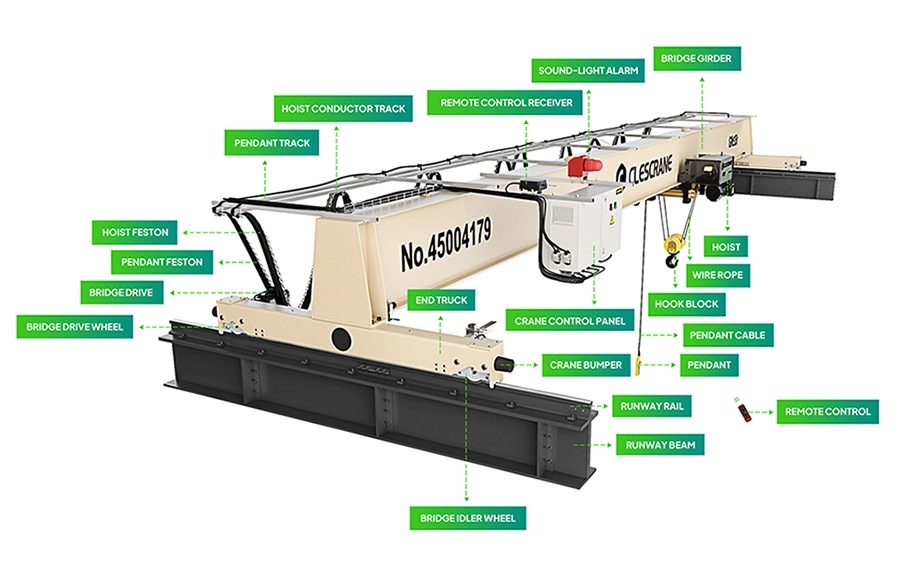

4. Crane girders made of computer-optimised box sections.

5. End carriages of torsionally rigid, welded box-section design.

6. Wheel group with adjustable structure, to prevent the rail from gnawing.

7. Crane is controlled by Three-In-One mechanism with frequency conversion, to reduce the equipment noise.

8. Overload limiter, height limiter, Stroke limiter, photoelectric limiter and other security measures are equipped according to different working conditions, crane black box with recorded analysis functions can be added based on the customer requirements.

9. Lifting capacity: 1~20 t, non-standard customized crane can be produced.