Clescrane CHD series double girder overhead cranes offer exceptional load capacity for a low deadweight. Powerful and agile, with a capacity of up to 100 tons, it is particularly good for general manufacturing, workshops, and assembly lines. The load hook can be raised between the two crane girders, which allows large lifting heights to be achieved.

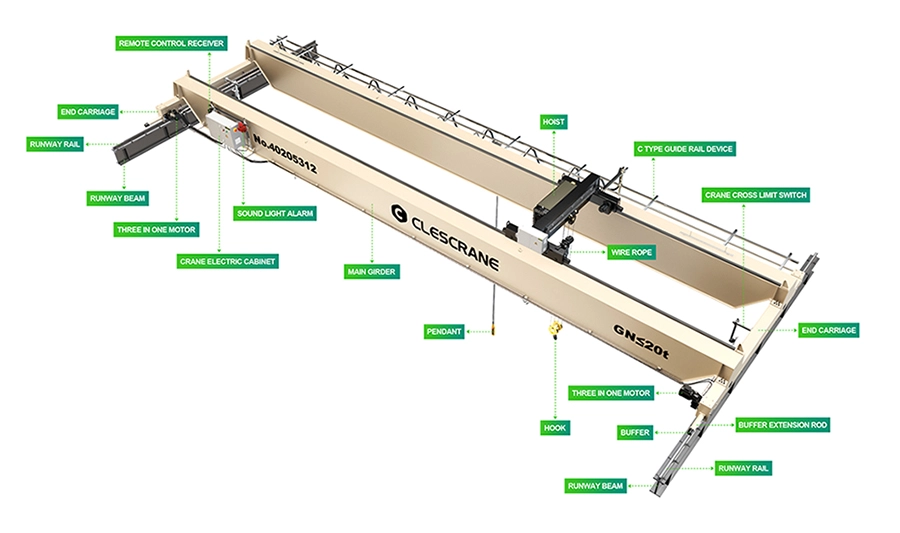

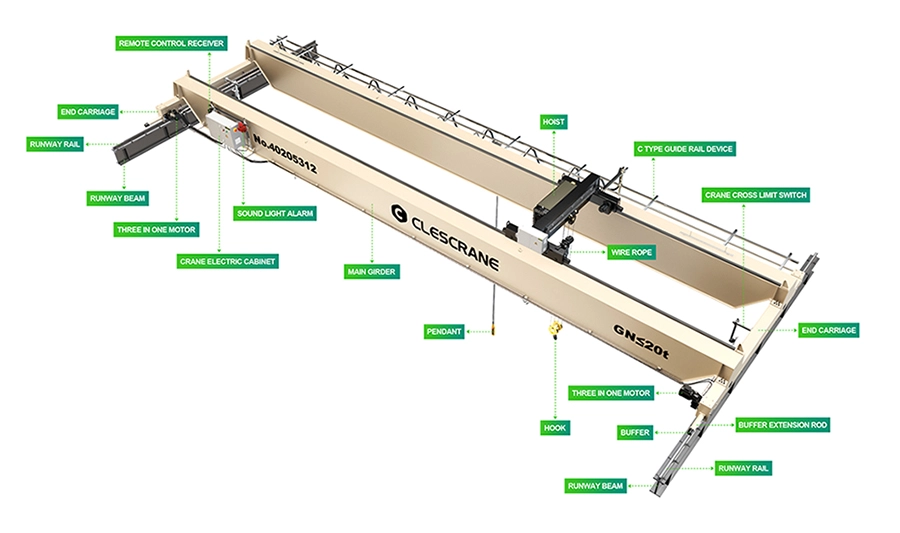

Supplied with CH series wire rope electric hoists

1. Design is based on FEM1.001 and CMAA70 standards.

2. Low deadweight reduces investment layout – crane girders made of computer-optimised box sections.

3. Crane girders can be adapted to building structure requirements.

4. Optimum utilisation of the available height and space thanks to compact travelling hoist design (minimum approach dimensions and large hook path).

5. End carriages of torsionally rigid, welded box-section design.

6. Modular design of end carriages and wheel sets. Wheel group with adjustable structure, to prevent the rail from gnawing.

7. Overload limiter, height limiter, Stroke limiter, photoelectric limiter and other security measures are equipped according to different working conditions, crane black box with recorded analysis functions can be added based on the customer requirements.

8. Crane control to meet application requirements: via radio control, control pendant or cab control (optional).

9. Maintenance platform and accessible crab facilitate maintenance of building interior fittings (optional).

10. Lifting capacity:1~100 t, non-standard customized crane can be produced.

Class A – This denotes standby or infrequent usage, such as cranes found in power utilities or motor rooms, where precise handling of equipment at slow speeds with long idle periods between lifts occurs.

Class B – This denotes light service, such as cranes used in repair shops or light warehousing, at slow speeds, with up to five lifts per hour up to maximum rated capacity.

Class C – This is for moderate service, such as those cranes installed in machine shops, including handling an average of 50% of the rated capacity up to 10 times per hour.

Class D – This is for denoting heavy service, such as cranes deployed in heavy machine shops, foundries, container yards, and more, where loads of 50% of the rated capacity are handled constantly.

Class E – This is for severe service, such as cranes found in scrap yards, cement mills, lumber mills, and more, where the crane makes 20 or more lifts per hour at or near its rated capacity.

Class F – This denotes continuous severe service, including custom-designed specialty cranes, that handle loads approaching the maximum rated capacity non-stop under extreme conditions.