Features of CHEX series explosion proof wire rope hoist

1. Explosion-proof class upto EX II CT4

2. 2-speed hoisting motor with thermistors

3. 2-speed pole change trolley motors with thermistors(for hoists with trolley)

4. Hoist upper and lower limit switches operated by the rope guide

5. Electro-mechanical overload protector

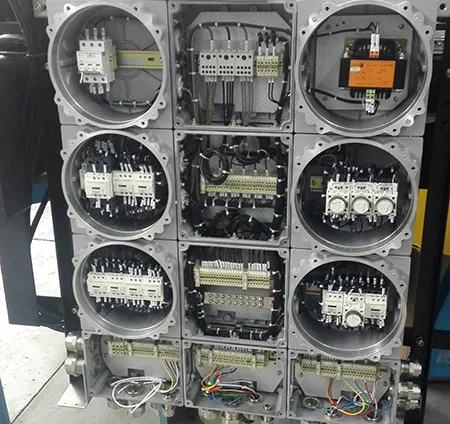

6. Hoist electrics with main contactor and 48V contactor control

7. Motor protection IP66 according to EN 60 529

8. Push button box with an emergency “stop” button

9. Ergonomical hook with safety latch

Class A – This denotes standby or infrequent usage, such as cranes found in power utilities or motor rooms, where precise handling of equipment at slow speeds with long idle periods between lifts occurs.

Class B – This denotes light service, such as cranes used in repair shops or light warehousing, at slow speeds, with up to five lifts per hour up to maximum rated capacity.

Class C – This is for moderate service, such as those cranes installed in machine shops, including handling an average of 50% of the rated capacity up to 10 times per hour.

Class D – This is for denoting heavy service, such as cranes deployed in heavy machine shops, foundries, container yards, and more, where loads of 50% of the rated capacity are handled constantly.

Class E – This is for severe service, such as cranes found in scrap yards, cement mills, lumber mills, and more, where the crane makes 20 or more lifts per hour at or near its rated capacity.

Class F – This denotes continuous severe service, including custom-designed specialty cranes, that handle loads approaching the maximum rated capacity non-stop under extreme conditions.